Products

Many Industries, One Reliable Partner!

Many Requirements – One Concept!

Requirements in the food industry have increased significantly in recent years:

Systems must be robust and solid, capable of withstanding high cycle rates and continuous operation – all while maintaining low operating and maintenance costs. We can meet these demands. The proven stable construction of our systems guarantees maximum durability and a very long service life. According to our customers, this results in an exemplary low total cost of ownership.

Products

for Customised Solutions

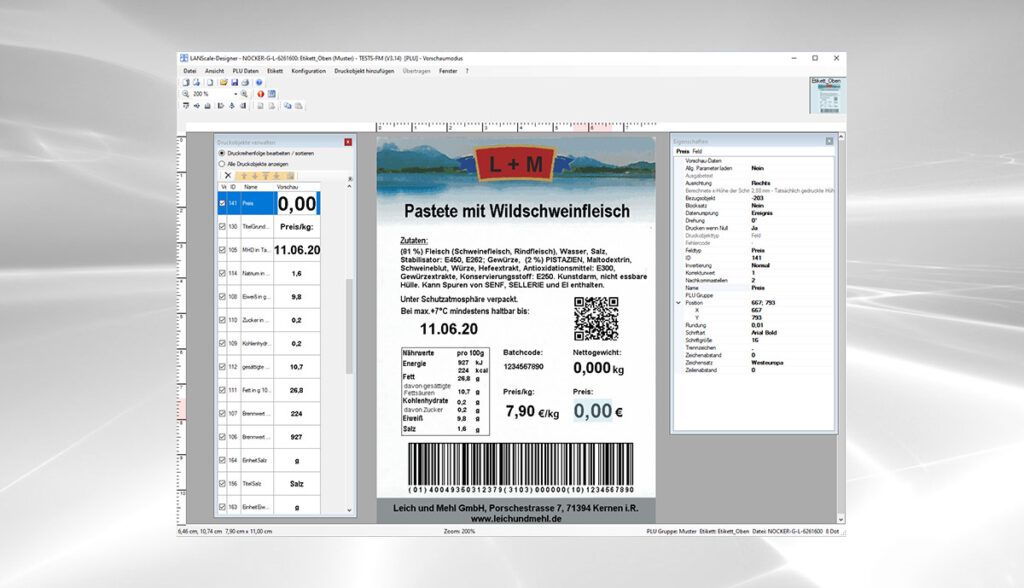

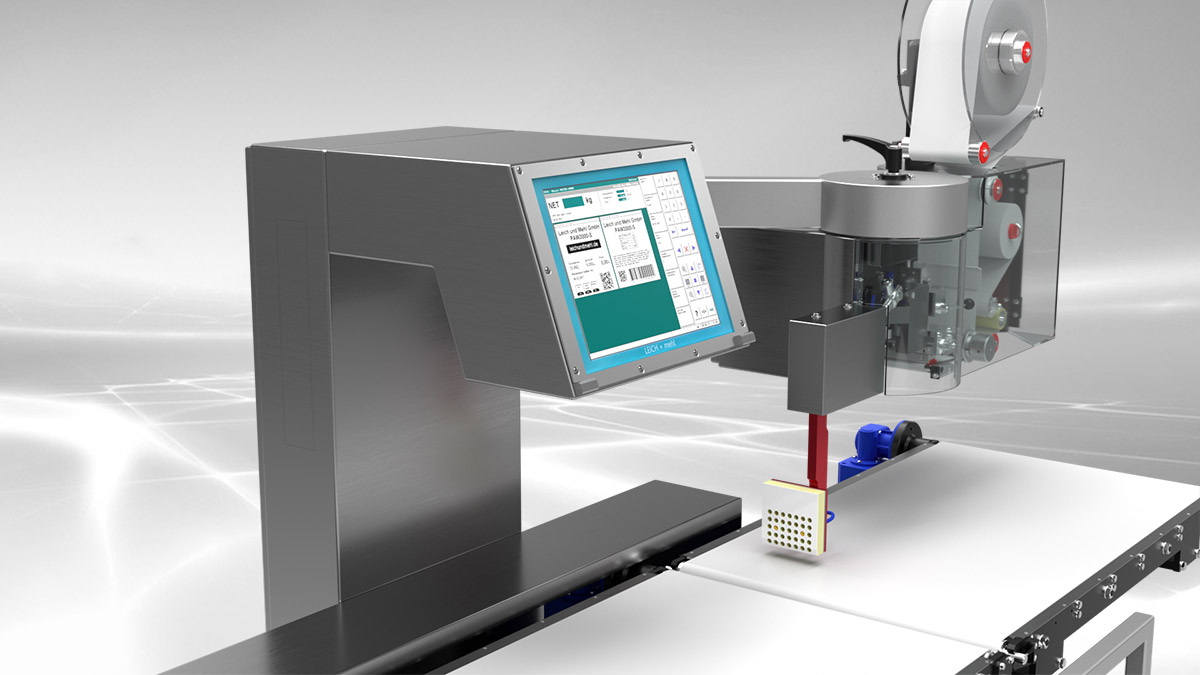

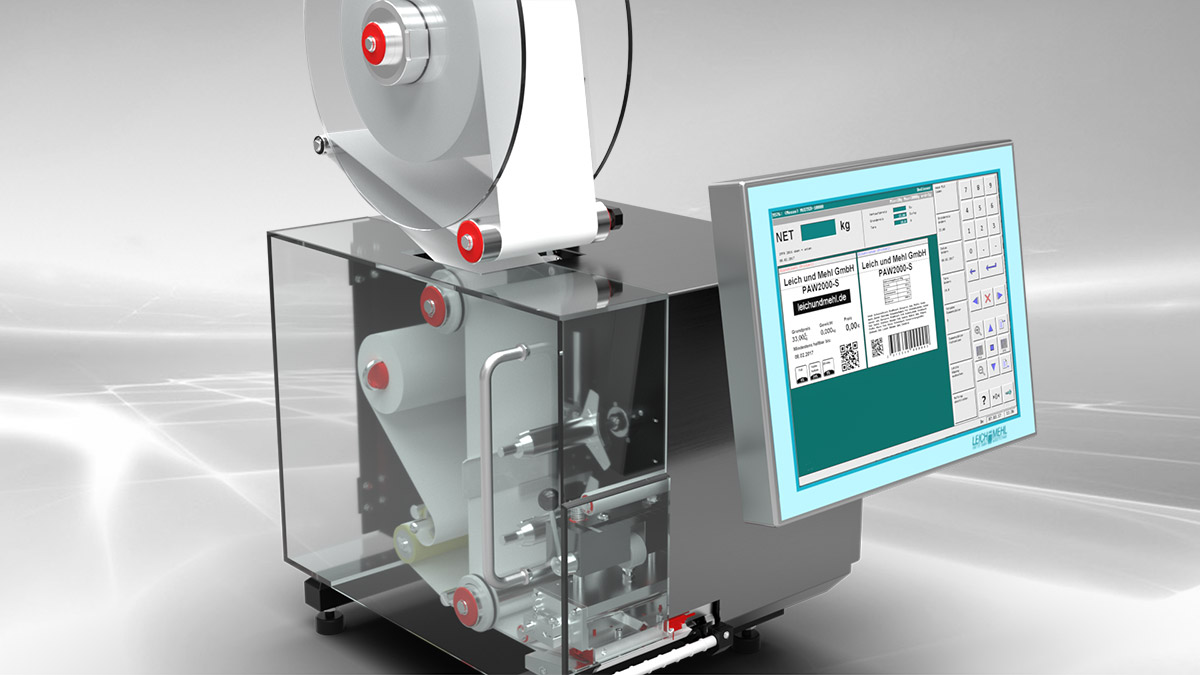

The control units of our systems are based on industrial PCs. Thanks to an open XML data interface, integration into ERP is seamless. For optimal user-friendliness, label layouts can be designed directly on the large touch display of the machines.

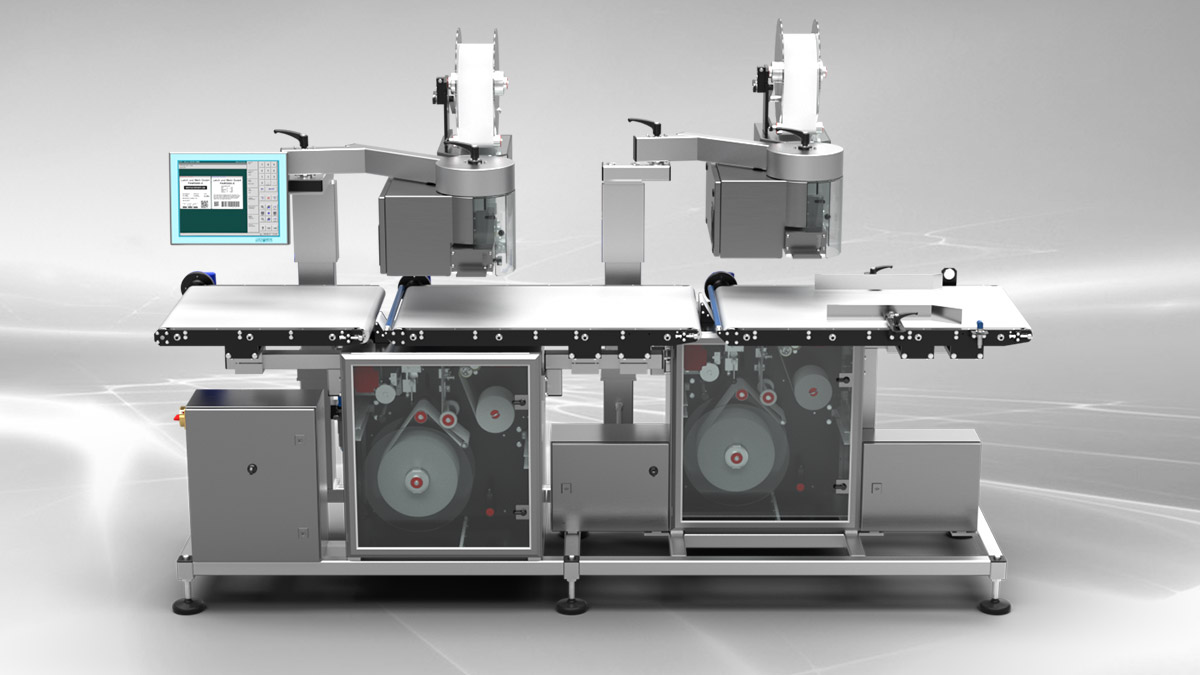

All our systems are designed for ease of operation and maintenance. Their accessible modular construction ensures hygienic design, easy cleaning, and quick replacement of individual functional components and wear parts.

If support is ever required, we are able to assist our customers by using a remote and maintenance module for quick access and easy service.

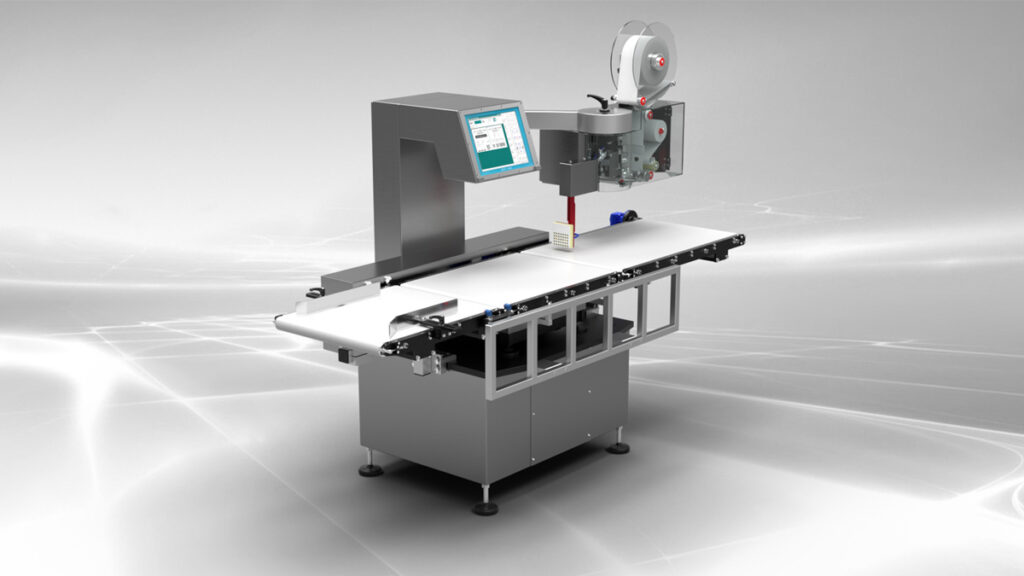

Our solution for highly automated production lines. All necessary adjustments during product changeovers occur automatically. Optional: the PAW3 can be equipped with a fully automated camera system for quality control of the print image. The camera system automatically recognises deviations on the label and does not need to be taught in. It can also be used to check whether the correct label roll has been inserted.

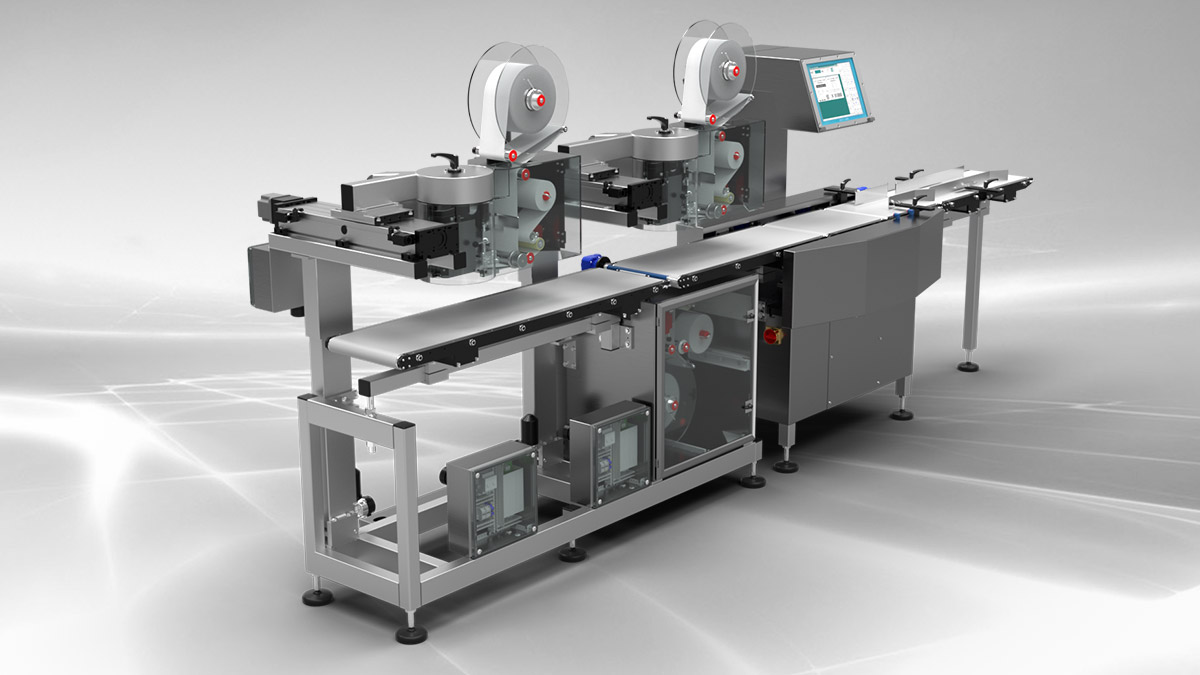

Available in various models for different weighing ranges, product types, and sizes. It offers connectivity for multiple printers, allowing flexible labelling from the top, bottom or laterally.

Our solution for labelling large items up to 30 kg. Available in various models for different weighing ranges, product types, and sizes. It offers connectivity for multiple printers, allowing flexible labelling from the top, bottom or laterally.

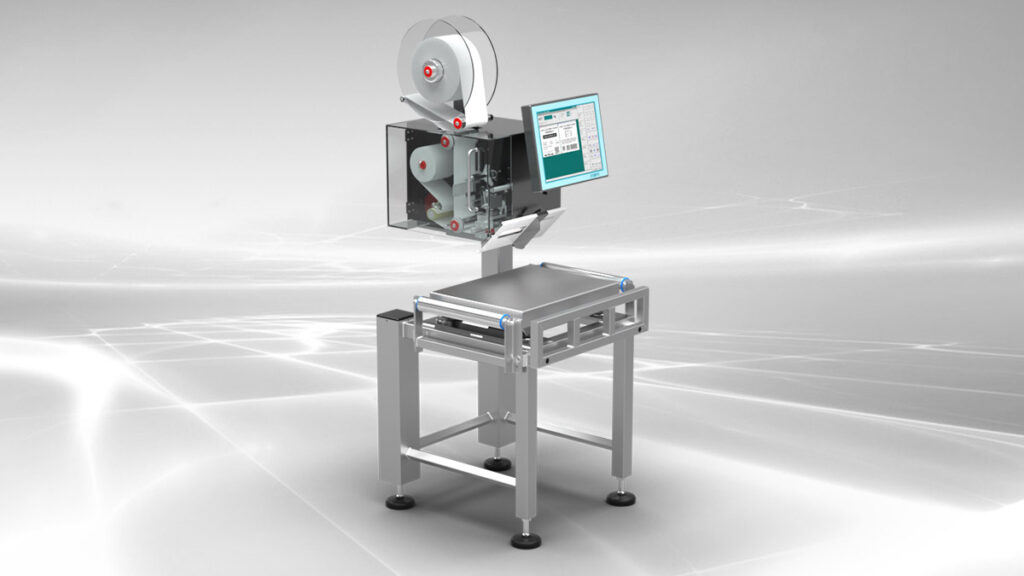

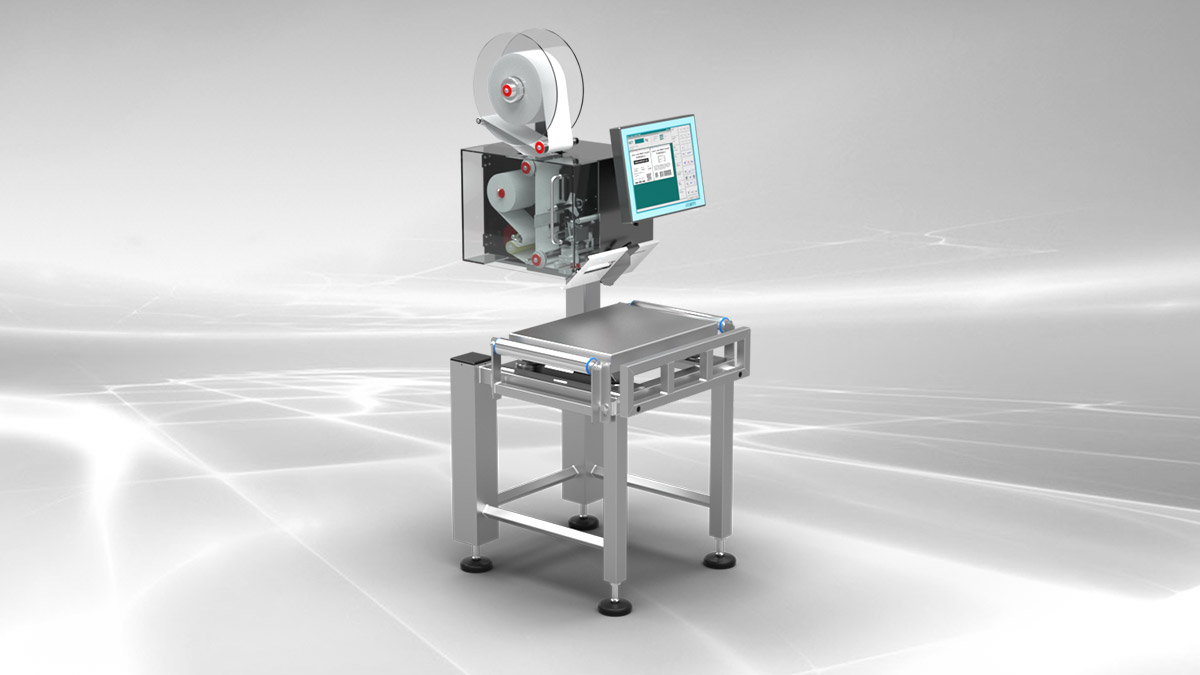

A semi-automatic labelling system available in table, stand or frame versions (up to 60 kg). Optional: with a roller conveyor. Additional printers and accessories can be connected.

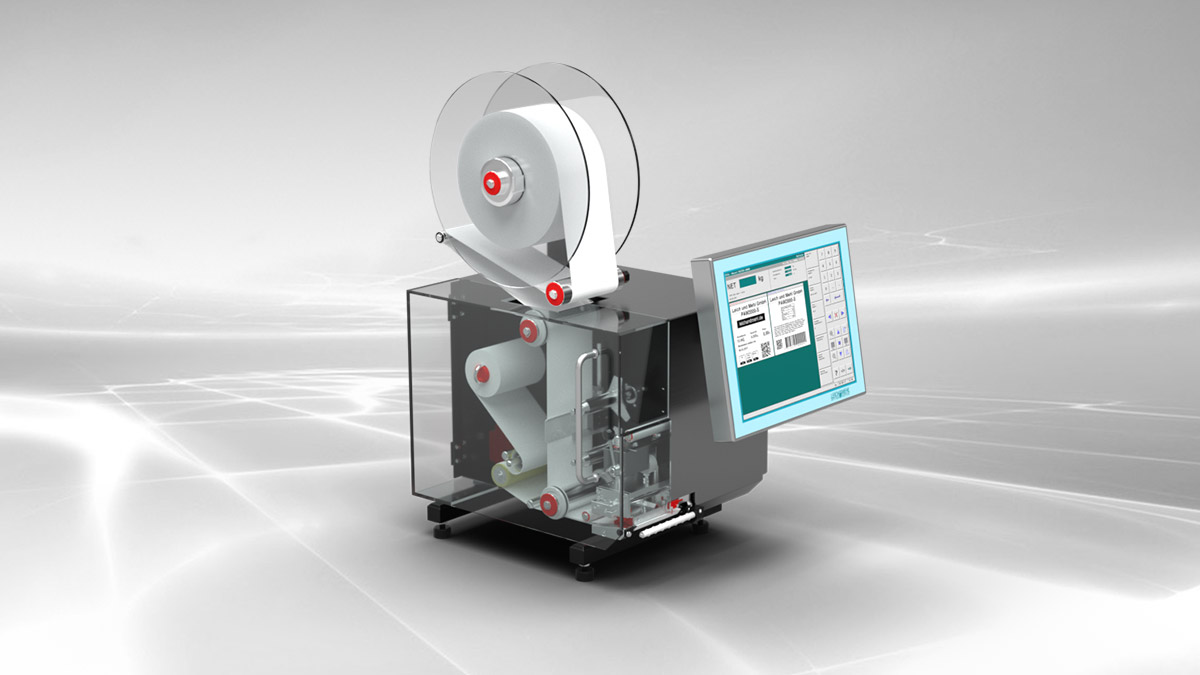

These label printers, built to match the PAW series’ robust standards, deliver up to 300 mm/s print speed and can print up to 200 labels per minute.

A label print-and-apply system with its own control unit in a rugged industrial design. Labels can be applied to the top, bottom or laterally.

Includes PC applications for all operational needs – from label design and connection to ERP systems or other databases to production data analysis and system status monitoring.